FOR IMMEDIATE RELEASE:

FOR IMMEDIATE RELEASE:

May 29, 2020

John W Rampe

Taper Tool

440-352-8995

jrampe@torquetrans.com

Looking to design or select the perfect sprocket for your chain drive system? Then you have come to the right place. Whether you're a seasoned engineer or a DIY enthusiast, our easy-to-use sprocket pitch diameter calculator will help you determine the right pitch diameter ...

We are pleased to announce a new product offering at Torque Transmission. We now have SW-3 & SW-4 Miniature Worm Gear Right Angle Gearboxes available in the ratios of 5:1, 10:1, and 20:1. The output shaft diameters on these drives range from 0.1873" on the SW-3 to 0.2497" on the SW-4.

Bearings literally make the world go round. They are called “bearings” because they “bear” the stress of an application’s moving parts.

A manufacturer of satellite and telecommunications equipment, developed a television reception satellite dish for mounting atop recreational vehicles. The design requires a system of three uniquely designed custom pulleys that govern the raising, lowering, and rotation of the dish.

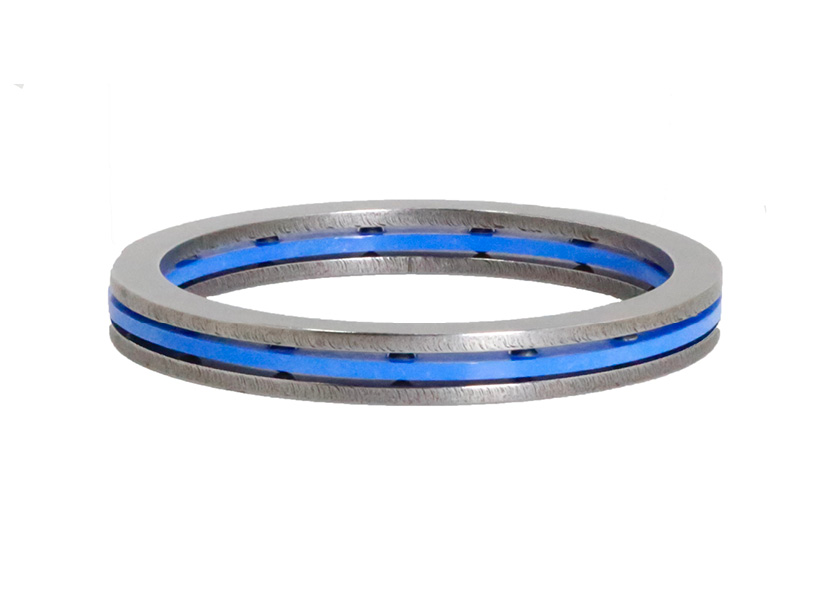

The electric vehicle market is exploding from the manufacture of cars, scooters, mobility carts, and bicycles. One element they have in common is searching for lightweight components to meet their weight requirements. Every pound a cart or scooter weighs requires so much energy to move it one ...

The electric vehicle market is exploding from the manufacture of cars, scooters, mobility carts, and bicycles. One element they have in common is searching for lightweight components to meet their weight requirements. Every pound a cart or scooter weighs requires so much energy to move it one ...

A New Year brings new resolutions. In our case, we are recommitting to an old mission. In everything we do here at Torque Transmission, we are attempting to help our customers solve problems. This year, we intend to optimize every aspect of our business to make your lives run more smoothly.

Now, more than ever, where your parts are made makes a huge difference. With disruptions in the supply chain across the globe, buying American Made is on everyone's mind. We thought this example from a few years ago was enlightening and hope you enjoy this re-posted article...