|

Material: |

6/12 Nylon 33% glass-reinforced with metal inserts |

|

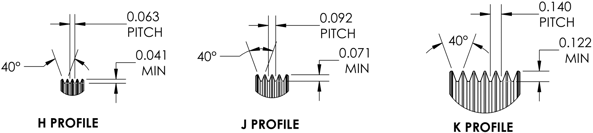

Rib Profiles: |

H, J, and K Pitch |

|

Grooves: |

2 to 30 |

|

ID: Bore |

Standard bores in inch and metric, Keyway and setscrews, D-Bore |

|

OD: |

H Profile: 0.50" Min to 8" |

• A Multi-V Nylon Pulley is also known as a Multi-Grooved Pulley or Multi Rib Pulley

• This nylon pulley features multiple V-shaped grooves or channels on the pulley face, hence the name "Multi-V."

• The V-shaped grooves provide increased surface area for the belt to contact the pulley.

• Allowing the belt to sit securely and transmit rotational force efficiently, minimizing slippage and maximizing power transfer.

• Proper tension is crucial for the performance and longevity of the Multi-V belt.

• Run on smaller diameter pulleys

• Transmit high torque loads at high speeds.

• Run quietly without vibration.

• The more compact the design and lighter the weight of drive components, the lower the drive inertia

• For OEM applications using an H, J, or K pitch

• Molded Nylon 6/12 has a tensile strength of 22,000 psi, able to handle shock loads, high speed, and continuous use.

• Nylon is an engineered, 33% glass-reinforced material, offering many advantages over other pulley materials. Nylon is half the weight of aluminum and one-seventh the weight of steel. Less inertia (less weight) means quicker starts, stops, and reverse actions.

• Multi V nylon pulleys cost, on average, 25-50% less than aluminum pulleys in volume quantities.

Poly V & Micro V Multi-Ribbed Pulley Applications:

|

|

Download Our Multi V Pulley Buying Checklist

Or...

Contact us with your specific Poly V & Multi V Pulley requirements for an individual evaluation and quote process

Poly V® is a registered trademark of Goodyear Tire & Rubber Company

Micro V® is a registered trademark of Gates Rubber Company

To Place an Order or Check Status of Order, Contact...

1246 High Street, Fairport Harbor, Ohio 44077 USA

CONTACT US