Many users of small power transmission equipment have shafts on motors or driven units with flats. The flat "D" is usually on shafts of less than 1/2" diameter. The small size of these shafts makes putting a normal keyway in the shaft impractical for either end use or economic reasons. In light power drives, torque is generally low, but a positive anti-torque device is needed.

"D" flats have many advantages over keyways or plain round shafts. A flat gives a setscrew a better bite than on a round shaft and can also make removing a device easier. "D" flats prove to be less bothersome than keyways which saves time in assembly of components.

Many applications require a metal or aluminum insert in a molded pulley. This insert can be broached with a "D" flat. The broaching operation is performed on the insert prior to the molding operation. This assures the concentricity of the primary bore to the pulley pitch diameter. In most instances, a T.I. R. of .005 is the concentricity tolerance obtainable between the bore and the O.D. In the molding process, the insert is held in place on a tooling component through the bore when the pulley is formed. Tooling costs for having the broach made to the specification of the "D" flat can vary depending on the specific parameters of the bore.

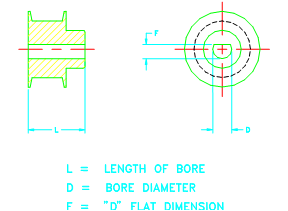

When a "D" bore is specified, it is very important to know the precise dimensions of the bore. There are few standards for "D" flat dimensions and these dimensions vary from manufacturer to manufacturer as well as many have been developed by in-house users. Tolerances on the bores and the flat should also be noted when ordering parts with the "D" bore.

The drawing below shows the 3 dimensions necessary to properly specify a "D Bore:

When you have an application for a "D" flat, contact Torque Transmission for assistance with your specifications and design of a cost effective solution.