A timing pulley is a cogged or cross-tooth pulley with the belt tooth matching the pulley tooth, much like a chain and sprocket. U.S. Rubber developed the first timing pulleys or synchronous pulleys and belts in the 1940s. As the name synchronous implies, timing pulleys were first used to keep two shafts in synchronous. Timing pulleys are designed to fit specific shaft sizes and types, ensuring precise alignment and secure operation. It is in the last 60 years that the timing pulley and belt are considered a positive drive alternative to chain and a replacement for friction drives, such as V-belts.

We at Torque Transmission continue to improve upon this tradition with our time-tested, precise, and reliable timing pulley solutions.

Timing belts offer a broad range of innovative drivetrain solutions; these drives employ the positive engagement of two sets of meshing teeth. Hence, no slippage and almost no backlash, maintaining a constant speed ratio, all extremely important in any application and more so in automated machinery requiring indexing or sequencing.

Advantages of timing pulleys:

Timing Pulleys come with many distinct advantages, such as…

Note: Some profiles, such as FHT®, are to be discontinued and may not be available in the future.

Pulleys and belts can also be cut to custom widths or diameters to meet specific application requirements.

Timing pulleys play a critical role in applications where precise power transmission and synchronization are essential. Working seamlessly with timing belts, they ensure accurate motion control while minimizing slippage and maintenance issues.

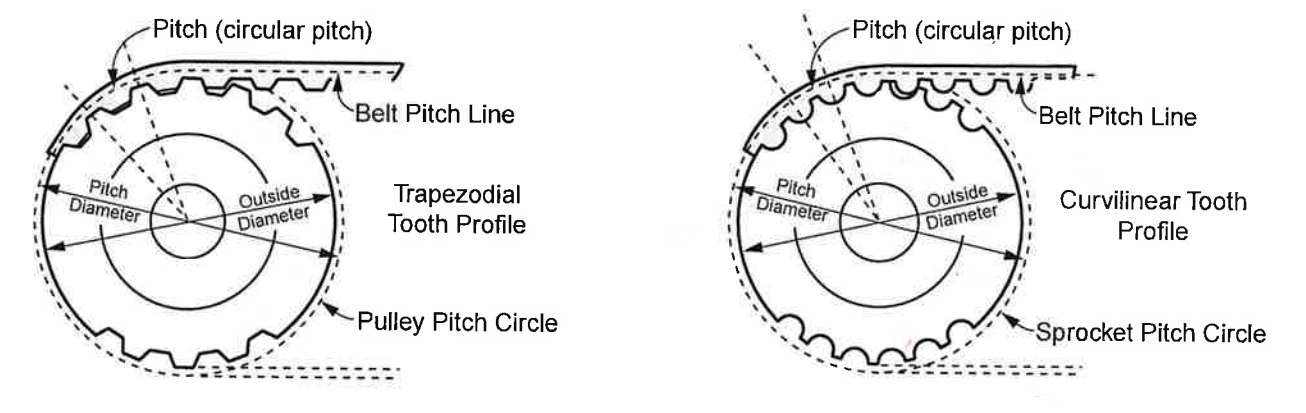

The tooth shape determines belt compatibility and performance.

Selecting the right material enhances system efficiency and durability:

Flanges and idlers are essential for maintaining belt alignment and tension. Flanges secure engagement between the belt and pulley, while idlers guide the belt and reduce wear—both extending system life and reliability.

Choosing the correct timing pulley depends on load, speed, and system layout. With a broad range of sizes, materials, and tooth configurations available, selecting the optimal pulley ensures efficient, dependable performance across your power transmission applications.

These timing pulley products are sold in a variety of sizes and configurations to meet different application needs. All products are designed for reliable performance in a wide range of drive systems. Customers can request custom bore sizes, modifications, or quotes for specific timing pulley products.

At Torque Transmission, we understand the importance of precise and reliable power transmission in your systems. All our product’s profiles, widths, and pitch diameters align with MPTA and ARPM Standards.

Together, we can identify your timing pulley needs and then create tailored solutions to meet them. For easier product selection, you can also watch our video tutorial on how to use the timing pulley selector tool.

To Place an Order or Check Status of Order, Contact...

1246 High Street, Fairport Harbor, Ohio 44077 USA

CONTACT US